100ºC – 1100ºC

Precision Thermal Processing

We design and build in-line furnaces, batch ovens and Atmospheric Pressure Chemical Vapor Deposition systems with conveyor belt, roller, and elevator transport methods.

Why SierraThermal

If you want a successful thermal processing solution, SierraThermal is the answer. We have 30+ years of thermal processing experience and expertise that provide peace of mind in knowing you’ve partnered with a company that can meet any thermal processing challenge.

Formerly known as Schmid Thermal Systems, we have conquered incredibly difficult production requirements by working in close collaboration with our customers to create solutions where none existed. We have built long-standing relationships over decades of collaboration with our suppliers to create a reliable foundation for quality and consistency. From thick film firing furnaces and reflow ovens, to annealing ovens and IR lamp furnaces, you can rely on SierraThermal to meet your thermal processing needs.

Innovative, quality furnaces and ovens for the worldwide microelectronics, photovoltaics, and glass processing industries

SierraThermal has and continues to be at the forefront of revolutions in photovoltaics and microelectronics processing. We design and build in-line furnaces, conveyor furnaces, elevator batch ovens and Atmospheric Pressure Chemical Vapor Deposition systems that deliver operating temperatures from 100°C up to 1100°C using high tech insulating materials and world class control systems.

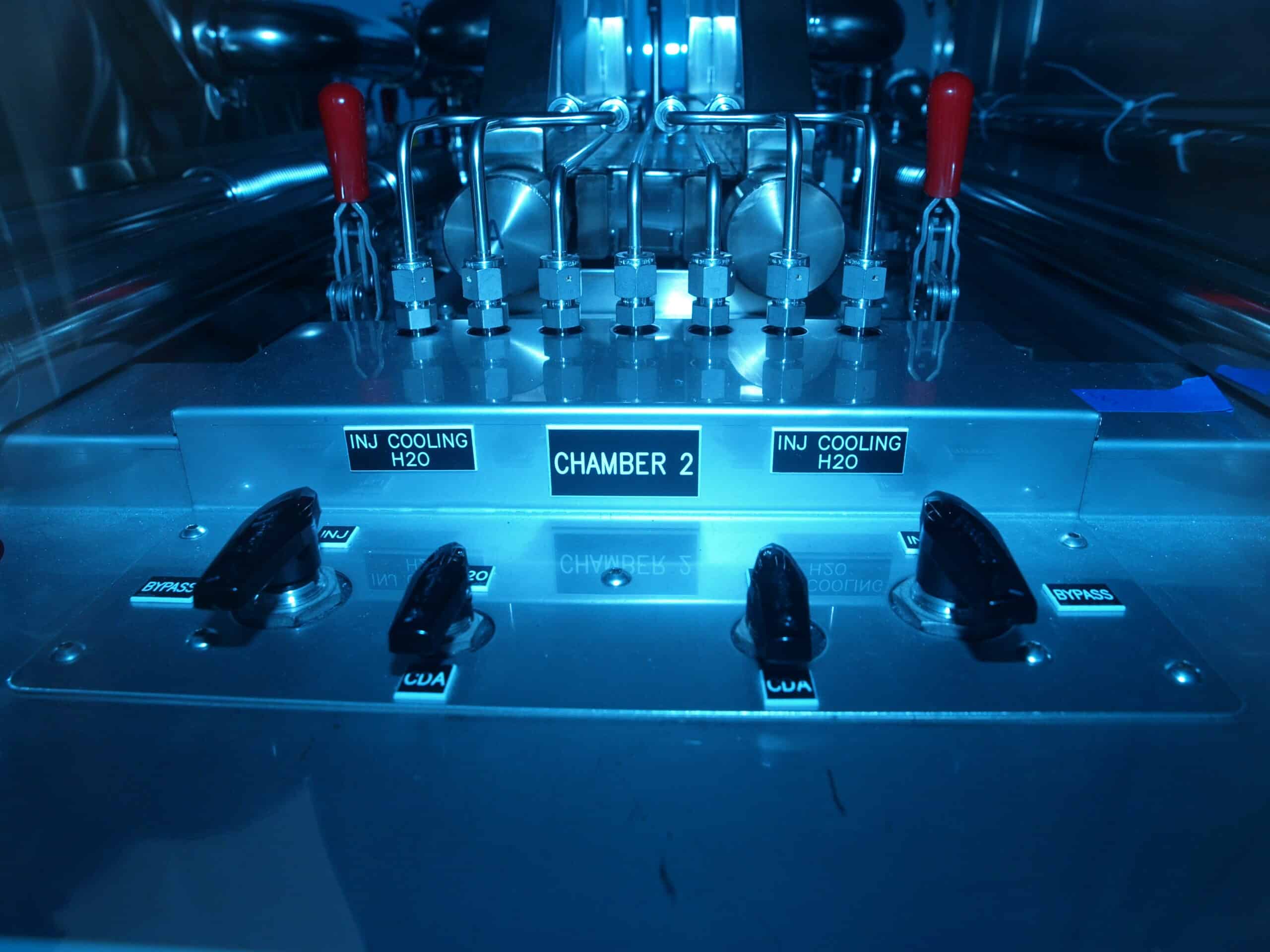

The Furnace Monitoring System (FMS) is the culmination of decades of thermal processing expertise, and incorporates the latest technology in digital controls and monitoring systems.

A well-established global network of sales and service experts keep us informed, engaged, and ready to support our many customers around the world.

We are also working with customers on forward-looking products like energy storage and glass related processes.

3,000+ furnaces and counting

With more than 3,000 furnaces shipped, SierraThermal has an excellent reputation for quality in the markets we serve. Many of our furnaces are still in service after more than 20 years of operation. This reflects the engineering expertise and design excellence that are at the heart of every SierraThermal installation.

Cost Savings

SierraThermal is the lowest cost alternative for your processing needs. Our equipment minimizes capital and operating costs by utilizing multiple tiers of graded, power-saving insulation materials combined with world class control systems. This provides a low cost of ownership by minimizing facilities and maintenance requirements.